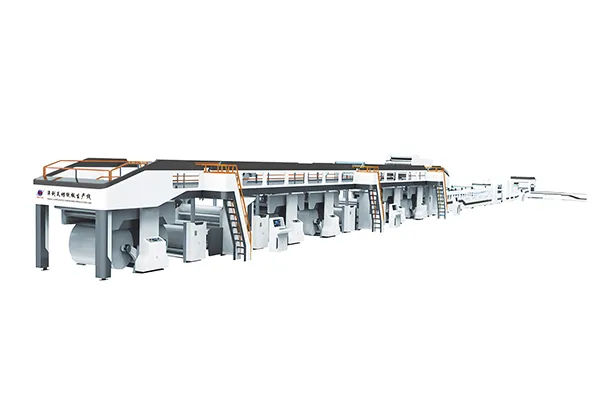

7-layer Corrugated Cardboard Production Line

- Production Speed Range: 120–200 m/min (customizable to customer requirements)

- Maximum Paper Width Options: 1.8 m, 2.0 m, 2.2 m, 2.5 m, 2.8 m

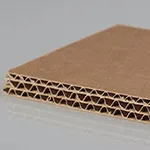

7-Layer Corrugated Cardboard

- Structure: Three corrugated medium layers (e.g., ABA flute) combined with four linerboard layers

- Thickness: 7–10 mm

- Ultra-High Strength: Edge crush resistance ≥ 7000 N/m, offering durability close to wooden crates

7-layer Corrugated Board Production Line Configuration

Technical Parameters

| Parameter | Specification |

| Slitting Accuracy | ±1 mm |

| Cross-Cutting Accuracy | ±1 mm |

| Surface Paper | 80–250 g/m2,Ring Crush Index ≥ 8 N·m/g (moisture content 8–10%) |

| Core Paper | 80–175 g/m2,Ring Crush Index ≥ 5.5 N·m/g (moisture content 8–10%) |

| Inner Liner | 80–250 g/m2,Ring Crush Index ≥ 6 N·m/g (moisture content 8–10%) |

| Flute Combinations | A,B,C,D,E,F,EF,AC (customizable according to customer requirements) |

Remarks: The above speed indicators are based on a production width of 1800 mm, meeting the specified paper standards, with heating components operating at a surface temperature of 175°C.

Features

- Intelligent Control

The new production line is equipped with IoT sensors for real-time monitoring of humidity, temperature, and tension. - Energy-Saving Design

Heat pump technology replaces gas drying, reducing energy consumption by up to 30%. - Pre-Printing Integration

The 7-layer corrugated cardboard production line can be integrated with high-definition printing to achieve a one-stop process from board production to finished products. - Tailored Configurations

Production line setups can be customized based on product weight, transportation environment, and budget. For example, a 5- corrugated cardboard production line can be equipped with a moisture-proof coating machine or ground logistics system for enhanced performance.