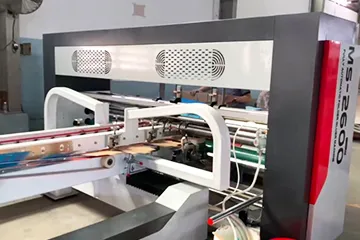

Yangli Pack specializes in the development of high-speed 3, 5, and 7-ply corrugated cardboard production lines, printer slotter die cutters, and related carton packaging equipment. Our solutions serve carton packaging machinery companies, corrugating roll manufacturers, and corrugated packaging operators.

We mainly provide standard models but also offer customized design services based on customer needs. Backed by our own R&D center and foreign trade company, and supported by a full management system that covers production, inspection, testing, sales, and after-sales service, we ensure on-time delivery and stable equipment performance. Choosing Yangli Pack means more than purchasing equipment, it means gaining a long-term strategic partner for upgrading your packaging capacity.

-

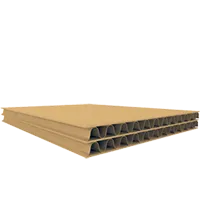

- Corrugated Cardboard Production Line A corrugated cardboard production line, often called a corrugator, is a continuous operation line that transforms rolls of base paper into corrugated cardboard sheets.

- 3-layer Corrugated Cardboard Production Line

- 5-layer Corrugated Cardboard Production Line

- 7-layer Corrugated Cardboard Production Line